How to Cut and Solder LED Strip Lights

It is quite likely if you have purchased an LED Strip Light or kit and have cut the strip or trimmed it to length you will likely have an offcut of Strip. The offcuts can be used elsewhere. There are easy fit connectors available like this:

They are not as reliable as a soldered connection, and the connectors are usually too wide to fit into an Aluminiun Profile or Channel.

We have provided a brief guide of how to cut and solder new wires to LED Strips. Whilst there are many different types of Strip Lights available, this principle applies to pretty much all of them.

NOTE: When soldering always use a suitable extractor fan, or do so in a well ventilated area and wear a suitable mask.

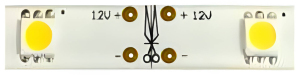

On most Strips you will notice there are cutting points at 35mm, 50mm, or 100mm intervals.

Cut the light strip along the line, or between the solder pads.

|

|

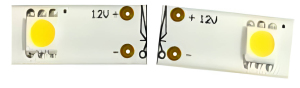

With a soldering iron gently apply a small amount of pressure on the copper solder pads, and touch the solder against the pad and the top of the soldering iron, the solder should flow onto the copper pads. This should only take 1 or 2 seconds. Be careful when soldering that you do not overheat the pads as this heat can damage the pad and the LEDs, a small dab of flux paste helps with a fast solder connection.

|

|

Make sure the wire you use is rated for load. Apply a small blob of solder to each copper solder pad. Before soldering the wire to the pads it is best to apply a small amount of solder to each of the wires to tin the wires this will prevent the wires from becoming frayed and causing a short-circuit.

Then solder a red wire to the positive (+) solder pad, and solder a black wire to the negative (-) pads as shown. Usually the soldered joints are insulated to prevent accidental short-circuits and moisture ingress. Heat-Shrink Sleeve is ideal for this, use sleeve with a diameter just a few mm wider than the width of the LED Strip.

For LED Strip with with an overall protective coating the applied insulation should seal all the way up to and around the coating and to where the wires exit the heat shrink to prevent water ingress.